A car’s hydraulic lifter plays a crucial role in its engine, providing a key function in the oiling system. These components can become worn out over time, leading to a number of issues with your vehicle. Bad hydraulic lifters can cause decreased engine performance, increased fuel consumption, stalling, and difficulty starting up the car. If you suspect that your car has a bad hydraulic lifter, then it is important to have it inspected and serviced immediately. In this article, we will discuss the symptoms of bad hydraulic lifters, as well as the cost of replacement services for these components. By understanding the warning signs and repair costs associated with bad hydraulic lifters, you can help ensure that your vehicle remains in peak condition and avoid any unexpected maintenance bills in the future.

What Are Lifters?

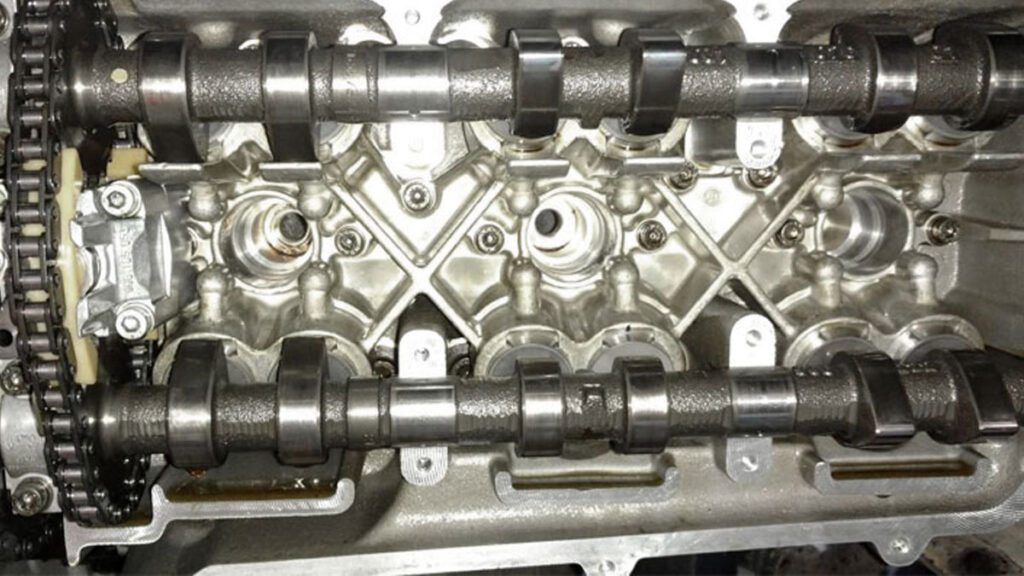

Hydraulic lifters, also known as hydraulic lash adjusters, solid lifters, and hydraulic tappets, are vital components of an internal combustion engine (ICE). They are responsible for allowing the rocker arms and valves to remain in contact even when subjected to extreme heat. Without them, the parts could bind against each other causing vibrations or rattling noises to occur. This can cause accelerated wear on the engine and decrease its overall lifespan.

Hydraulic lifters are designed to automatically adjust the valve clearance to ensure a minimal tolerance between the two parts is maintained. This ensures that there is no binding occurring from thermal expansion due to engine heat. The result is quieter operation, longer engine life, and less need for scheduled valve adjustments.

Manufacturers design hydraulic lifters using components such as a push rod, plunger, and adjusting nut. A push rod connects it to the camshaft while a plunger is pushed into contact with the rocker’s arm by spring pressure when cold but retracts when hot due to its special construction materials that expand when heated up. An adjustable nut maintains a set pre-load on the plunger which shifts it back into contact with the rocker’s arm once cooled down again.

How Do Hydraulic Lifters Work?

Hydraulic lifters are an essential component of any vehicle’s engine and have a crucial job: they effectively reduce the amount of noise generated by the engine when running. In a hydraulic lifter, the valve is connected to a small rod known as the rocker’s arm. Inside the hydraulic lifter is a combination of oil, plunger, and spring that creates clearance within the valve train, producing quieter driving conditions. The oil also helps to lubricate parts of the engine and reduces wear and tear, thereby reducing maintenance costs and extending its life.

However, if there is not enough oil pressure in the hydraulic lifter, it can affect its performance. This may result in unusual noises coming from the engine or even worse damage to other components such as the tip of the valve, rocker’s arm, or push rod – all costly repairs that need addressing quickly. To prevent this from happening, it is important to regularly check your vehicle’s fluids and ensure that there is an adequate level of oil pressure in your engine’s hydraulics system.

Hydraulic Lifter Location

The location of hydraulic lifters can vary depending on the vehicle’s make and model, but they are usually found at the top or bottom of your engine. If you have a push rod and rocker arm setup, then the hydraulic lifter might be located somewhere in between. It is important to note that regardless of what type of car you have, there will always be some form of mechanical lifter in place. Without a hydraulic lifter, the camshaft would be unable to move the valves correctly. As such, they are essential components in any engine and should be regularly inspected and maintained for optimal performance.

Bad Hydraulic Lifter Symptoms?

There are a few tell-tale signs that indicate when your hydraulic lifters may be malfunctioning. These include:

Sticky Lifters

A sticky lifter keeps itself in a contracted position instead of expanding and contracting. When the system cannot sustain oil pressure due to the immovable parts, it leads to internal hammering that produces more noise. Such damage can be avoided by ensuring regular maintenance is done on your vehicle’s lifters.

Noisy Lifters

Excessive noise that occurs during engine startup or idle is an indication of faulty lifters. This suggests a lack of oil pressure in the lifter, which can lead to other parts being damaged due to excessive wear and tear.

Inaccurate Valves

If your vehicle’s valves are not opening and closing properly, it is likely that the hydraulic lifter is not working correctly. This can cause your engine to run roughly or misfire as airflow cannot move in and out of the cylinders correctly.

More RPM Causes More Noise

If your engine is making more noise when the revs are higher, this could be an indication of a faulty lifter. Badly worn hydraulic lifters can produce more noise as the engine speed increases due to increased oil pressure and metal-to-metal contact.

Oil Leaks

Hydraulic lifters that are not operating correctly can cause oil leaks. This is due to the seals in the lifters becoming worn and allowing oil to escape. Regularly checking your vehicle for signs of oil leakage can help identify any potential problems with the hydraulic lifter system before they become more serious.

Misfires

Misfiring engines are a common sign of faulty hydraulic lifters. This can be caused by the lifters being unable to hold their adjustment or if they become stuck in a retracted position, which will lead to inaccurate valve timing.

Broken Pushrods and Dead Cylinders

Dead cylinders are a common problem and can decrease engine performance significantly. The main cause of dead cylinders is bad lifters, which can bend or break the pushrods they interact with. Pushrods are cylindrical metal tubes that are used to transfer motion from the cams on the lifters to the valves in the engine. When the lash adjuster is faulty or broken, the pushrods will also suffer and cause the corresponding cylinder to cease functioning.

Check Engine Light

Finally, your vehicle’s check engine light may come on if it is having trouble with the hydraulic lifters. If this happens, it is important to take your vehicle to a certified mechanic as soon as possible so that the underlying cause can be identified and any necessary repairs can be made.

If you notice any of the above symptoms in your vehicle, you should have it checked as soon as possible to ensure the problem does not become worse. A professional mechanic can help you diagnose the issue and provide a suitable solution so that your vehicle runs smoothly and efficiently.

What causes the hydraulic lifter to go bad?

Although automobile lifters are designed to last, sometimes they inevitably fail and require replacement. To understand why this happens, it is essential to be aware of the most common causes that lead to a malfunctioning lifter:

Engine oil and oil condition

The primary cause of a hydraulic lifter going bad is insufficient or incorrect oil levels in the crankcase, as this can cause a lack of lubrication or result in bubbles or aeration in the oil. If the engine oil is too thin, contaminated, or in poor condition, it can affect the functioning of the lifter. Low-grade oil will reduce its ability to lubricate and slow down the movement of parts. Contamination with sludge and debris can clog up important components and lead to a malfunctioning lifter.

In order to ensure that your hydraulic lifters remain in good condition, it is important to check the oil levels and quality regularly, ensuring that they are at the correct level and free from contamination. If you suspect any damage or decreased performance due to a faulty hydraulic lifter, it is recommended that you seek professional assistance as soon as possible.

Wrong viscosity rating

Oil viscosity is a critical factor for keeping an engine in good condition and performing optimally. Heavy-viscosity oils, such as 40W and 20W-50, do provide elevated oil pressure in warmer climates, but this can be inadequate for cold weather conditions, particularly during initial startup. This issue can be particularly noticeable with overhead cam engines, where the oil must travel farther vertically. On the other hand, light-viscosity oils, such as 5W-20 or straight 10W, are better suited for cold weather but can be too thin and not supply enough lubrication in hot temperatures. Therefore, most engine manufacturers recommend 5W-30 as a reliable all-season oil.

Lousy oil filters and screens

If you haven’t changed your oil filter in an extensive period of time, the resulting clog and restricted oil flow can cause a plethora of engine issues. As if that weren’t enough, a low-quality or aged filter may be to blame for triggering the blinking or steady warning light on your vehicle’s instrument cluster. In order to ensure that your hydraulic lifter operates properly, make sure that you check and change your oil filters and screens regularly.

Incorrect assembly

If the lifter has not been correctly assembled, it may not be able to function properly. This can cause the lifter to make sounds or become faulty, leading to a performance decrease and eventually failure. It is essential that you follow the instructions when assembling your hydraulic lifters in order for them to operate effectively and without incident.

Lash Adjustment

Hydraulic lifters are an important part of any engine and require careful adjustment. In order for the lifter to work properly, it must be set to ‘zero lashes’, which means that any pressure exerted by the cam or push rod is cushioned by oil inside its casing. If this adjustment is off, it can cause excessive wear on the cam and lifter, as well as bent push rods.

To prevent this, it’s recommended that solid lifters be adjusted every 30,000 miles or so. If this adjustment is not done in a timely manner, serious damage to the engine can occur. Therefore, it is important to ensure that your lifter adjustment is done correctly and regularly.

Old engine and lack of maintenance

As engines age, components start to wear down and could even become corroded or damaged. If the engine has not been well maintained, chances are that hydraulic lifters can malfunction due to worn-out parts and inadequate lubrication. Regular maintenance will ensure that all components remain in good condition and your engine is running optimally.

Wear and tear

Over time, hydraulic lifters can suffer from gradual wear and tear due to prolonged use. This can be caused by either a small crack or leak in the chamber that houses the oil, allowing air to enter and causing pressure issues. It can also be down to dirt and debris entering the system, which can prevent its proper functioning.

These are just some of the reasons that can cause a hydraulic lifter to go bad. In order to ensure that your engine is running smoothly and efficiently, it is important to check the condition of your hydraulic lifters regularly. If you suspect any damage or decreased performance, seek professional assistance as soon as possible in order to avoid further issues.

Engine Lifter Replacement Cost

Replacing an engine lifter can be a daunting task due to the various factors that come into play. While it’s possible to replace just one single lifter, it’s generally recommended to replace all of them in order to avoid future problems. The cost of a single lifter will range from $5-$30; but when replacing multiple lifters, the price can increase significantly depending on the type of engine and the number of valves present. It may be necessary to buy gaskets, bolts, and other components at a premium cost as well.

Labor costs for such replacement jobs can also be steep. Depending on the type of engine involved, it could take anywhere between 3-10 hours to complete the job – with labor rates typically ranging from $100/hr. This means that even if you manage to get cheap parts, you could still end up paying a hefty amount in labor charges alone. For instance, if you were replacing 16 lifters in an average V8 engine, it could cost around $1000-2000 in total (including parts and labor).

A more economical option would be buying refurbished lifters instead of new ones; however, this usually doesn’t make much difference for labor costs so it isn’t recommended unless there is no other choice available. Moreover, these parts may not perform as effectively as brand-new ones leading to potential problems down the line.

In conclusion, replacing engine lifters can be quite expensive due to both part and labor costs involved; however, it’s important for the performance and longevity of your vehicle so shouldn’t be neglected under any circumstances. Make sure you always work with experienced mechanics who use high-quality parts in order to keep your car running perfectly for years to come.

How Do You Fix A Bad Lifter?

One of the most common problems that may arise with an engine is a bad lifter, which is often characterized by a ticking sound. Fortunately, there are several solutions you can try in order to fix the issue and get back on the road in no time! Follow these simple steps below and soon enough your car will be good as new again.

Check the motor oil condition

The first step you should take when attempting to fix a bad lifter is to check the motor oil condition. If the oil has not been regularly changed, sludge buildup can occur and lead to a ticking noise emanating from the lifters. Even if you do change the motor oil regularly, it might still be low on its recommended level. It’s crucial that you use the right type of oil viscosity for your engine when changing it.

Use cleaning additives

Another solution is to use special cleaning additives. Simply changing motor oil may not be enough to fix bad lifters–you might need to flush and clean out any excess sludge in the engine as well as use additives like SeaFoam High Mileage or Liqui Moly Hydraulic Lifter Additives. These formulations will help benefit hydraulic lifters, valves, push rods, and rockers’ arms so they can run more efficiently again.

Replace the lifter

In some cases, replacing bad lifters might be necessary. If only one of them is broken, then all of them should be replaced since they could have incurred wear too. On older engines with solid lifters, however, just an adjustment may be enough to make things work better again. A service technician should also check if there’s proper clearance between valves and camshafts as well as pushrods in order for these parts to remain effective as well.

Inspect And Maintain Regularly

Ultimately, fixing a bad lifter requires careful inspection and maintenance in order to ensure that your engine remains at peak performance levels over time. Regularly checking and changing your motor oil can go a long way towards preventing such issues from occurring while making sure other components are properly lubricated and functioning correctly will also help prevent further damage down the line.

With these measures in place, you’ll be able to keep your car running smoothly for years into the future!

What Does a Bad Lifter Sound Like?

The sound of a faulty hydraulic lifter can be a cause for concern. It’s important to be aware of the specific noises that indicate a problem, as identifying and fixing it before it becomes worse can save you hundreds of dollars in repairs. A bad lifter will emit a continuous tapping sound, which takes on an increased rate over time. Additionally, you may hear a loud banging noise for more severe lifter issues. This sound can occur regardless of whether your engine is hot or cold. By understanding what a bad lifter sounds like, you can take the necessary steps to repair it quickly and efficiently.

How to Quiet Noisy Lifters?

To avoid noisy valve lifters, keep these tips in mind:

Regular oil changes

Regular oil changes are essential for preventing noisy valve lifters from developing. Without regular oil changes, the engine oil can become dirty or have low levels of lubricant, thereby damaging the lifter and leading to potentially hazardous conditions. It is also important to use the correct type and grade of oil; using synthetic oil or high-mileage motor oil is recommended for better results.

Use an oil additive

In addition to regular oil changes, an excellent way to help avoid noisy valve lifters is by using an oil additive like Liqui Moly or Marvel Mystery Oil. These additives can clean and condition the engine parts, such as the rocker arms and valves, while also improving the quality of the engine oil. Moreover, these additives are completely safe and cost-effective methods that could save you money in the long run.

Adjust the Lifter Spacing

Finally, if even after performing these steps your vehicle’s noise persists — even though there is nothing wrong with it — it might be necessary to get a professional mechanic to adjust the spacing between the lifter and other components of your engine. This will ensure that everything is working properly and functioning optimally according to manufacturer specifications. Vehicle manuals usually provide optimal information regarding ideal lifter spacing.

By following these tips, you can easily prevent noisy valve lifters and enjoy a quieter ride. It is important to note that if you are not comfortable performing any of the above-mentioned steps, or if it has been more than two years since your last oil change, it would be best to seek professional help.

Can you drive a car with bad hydraulic lifters?

The short answer is yes, but it will not be an enjoyable experience. Bad hydraulic lifters cause several issues that make driving a car with them difficult and uncomfortable. The most common symptom of bad hydraulic lifters is excessive engine noise, as the faulty part prevents proper oil flow and lubrication to key parts of the engine. This lack of lubrication can lead to accelerated engine wear, an inability of the valvetrain to operate correctly, and a decrease in overall performance. Poor fuel economy can also be expected, as the engine needs to work harder with faulty components. It is best to have this issue addressed by a trained mechanic or technician as soon as possible as delaying repairs can cause major damage that is expensive and time-consuming to fix.

In short, it is possible to drive a car with bad hydraulic lifters but you should expect an uncomfortable ride and poorer vehicle performance. If you suspect that your car has faulty parts, it is best to have them fixed as soon as possible by a qualified technician in order to avoid further damage.

How do you clean dirty or clogged hydraulic lifters?

Cleaning your hydraulic lifters is a great way to keep them functioning properly and prolong their lifespan. There are several steps involved in the process, including adding engine flush cleaner, running the engine, draining the oil, and replacing both the oil filter and oil. Understanding each step is essential for the proper maintenance of your vehicle’s hydraulic lifters.

Materials Needed

Before beginning the cleaning process, you will need to have certain items on hand. These include your preferred engine flush cleaner, jack stands, an oil drain pan, an oil filter, a replacement oil drain plug (in case the old one is damaged), and new oil following your car’s specifications. Be sure to research what exactly your specific vehicle requires as well as follow any instructions given by both manufacturers of engine cleaners and vehicle manufacturers.

Step 1: Adding Engine Flush Cleaner

The first step in this process is adding your chosen engine flush into the engine of your car. Open up the oil cap and add in a suitable amount based on how big your engine is. Make sure that you adhere to all directions found on the label of the engine flush product; if your engine is large enough it may require two or more bottles of cleaner instead of just one. When you’re finished with this part, make sure that you securely close off the cap once again before continuing on to Step 2.

Step 2: Running The Engine

After pouring in some of the engine flush detergents, it will be time to start up your car and let it idle for roughly 15 minutes worth of time. This allows for optimal results as far as getting rid of any dirt and grime build-up inside out. You may hear a decrease in noise coming from within your lifters due to them being slowly but surely cleaning out during this period; when that 15 minutes have elapsed then go ahead and turn off your car again afterward.

Step 3: Drain The Oil & Remove the Oil Filter

Placing an oil drain pan underneath your car’s oil drain spout, you will then be able to go ahead and empty out the existing oil from within. Once that’s done, unscrew the oil filter and set it aside so that you can replace it with another one later on.

Step 4: Replacing Oil Filter & Oil

Securely install the new oil filter and replace the oil in your car. Do your research to find out what type of oil is needed for your specific vehicle as well as how many quarts it needs.

Step 5: Allow Oil To Circulate

Turn on your car and let the engine idle for a few minutes before revving it up a few times. This allows the new oil to circulate throughout the engine and any rattling or noise should have subsided due to the lifters being successfully cleaned without having to remove them.

After following this process, your hydraulic lifters should be as good as new! With regular cleaning and maintenance, you can ensure that they’re in excellent condition and keep your vehicle running smoothly.

Finally, make sure not to forget about re-checking your car’s oil level after replacing it. Additionally, if possible inspect your lifters visually afterward–if there is still dirt present then repeat Step 1 again until satisfied with the results. Good luck!

How Can I Prevent My Lifters From Going Bad?

Here are a few simple steps you can take to help prevent your lifters from becoming damaged or broken:

Change your oil regularly

One of the most important steps to prevent your lifters from going bad is to keep up with regular oil changes. High-quality motor oil helps protect your engine parts and reduce wear, so it’s best to use a synthetic blend or full synthetic variety.

Use the correct oil viscosity

When changing your oil, make sure you’re using the correct viscosity for your engine. If you’re using too thin of oil it won’t provide enough lubrication and protection to prevent damage to your lifters.

Don’t overfill your oil

Overfilling your engine oil can lead to too much pressure in the system, which can cause your hydraulic lifters to wear out quickly. Make sure you follow the manufacturer’s instructions when refilling your engine oil and never exceed the specified limit.

Avoid using too many additives

Additives such as engine cleaners or degreasers can damage your hydraulic lifters. Make sure you only use motor oil as per the manufacturer’s guidelines and avoid using any additional products in order to protect your lifters from wear and tear.

Check your engine for leaks

Leaking oil can cause your lifters to become damaged, so make sure you regularly inspect your engine for any signs of leaks. If you find any, get them fixed immediately to avoid further damage to your lifters.

By following these simple steps, you can help ensure your lifters stay in good condition and keep your engine running smoothly.

How to extend the lifespan of hydraulic lifters?

Hydraulic lifters are an essential part of the engine’s functioning and it is important to maintain them in order to ensure a long lifespan. Here are some tips on how you can extend the longevity of your hydraulic lifters.

Check for signs of wear or damage often

Hydraulic lifters should be regularly checked for any signs of wear or damage. If you notice any cracks, leakages, or unusual sounds coming from your hydraulic lifters, it is best to replace them immediately to avoid further damage.

Replace old seals and gaskets

Old seals and gaskets are prone to leaking, leading to decreased performance and increased wear. Make sure to replace all worn-out seals and gaskets regularly in order to maintain the effectiveness of your hydraulic lifters.

Regularly lubricate the parts

Hydraulic lifters need to be properly lubricated in order to prevent friction between moving parts, which can cause wear and tear over time. Apply clean oil or grease on all the moving components at least once every month or as per the manufacturer’s specifications.

Clean up any debris or dirt

Foreign objects such as debris or dirt can get stuck inside hydraulic lifters, leading to decreased performance and increased wear. Make sure that you clean all nooks and crannies inside the engine compartment frequently in order to avoid this issue.

By following these simple tips, you can extend the lifespan of your hydraulic lifters and ensure that your engine is running smoothly. However, if you are having any issues with your hydraulic lifters, it is best to consult a professional mechanic for an accurate diagnosis and repairs.

Wrapping Up

From gaining an understanding of what lifters are and how they work to recognizing the signs of a bad hydraulic lifter to knowing the replacement cost and how to fix them, this blog post has provided an in-depth look at lifters! It is easy to see why they are such a critical component of our vehicle’s engines. As car owners, it is important that we be aware of the symptoms of bad hydraulic lifters so that we can address the issue sooner rather than later.

Luckily, keeping your hydraulic lifters clean and well-maintained can help reduce the chances of their going bad and needing to be replaced in the future. Keep these key tips and advice in mind to keep your engine components running smoothly – you won’t regret it! So don’t wait any longer – take action now and start caring for your engine’s lifters today!

Frequently Asked Questions

A: Yes, bad lifters can be one of the causes that lead to engine damage and failure. Symptoms of bad lifters include loud ticking noises coming from the engine, an increase in oil consumption, a noticeable decrease in power output, and misfiring. If left untreated for too long, bad lifters can cause further damage to other components such as valves, camshafts, and connecting rods. Therefore, it is important to have your lifters checked at regular intervals so that any potential issues can be identified and corrected before they cause serious damage.

A: A ticking noise from your engine is usually caused by a valvetrain problem, of which bad lifters are one of the possible sources. The ticking sound may be caused by the lifter not pumping up correctly or not pumping up at all, resulting in an inadequate amount of oil pressure being supplied to the valvetrain components and causing them to make a knocking sound. This ticking noise is often more noticeable when the engine is idling, but can sometimes be heard even when it’s running at higher speeds.

A: Yes, low oil pressure is one of the primary causes of lifter noise. This occurs when there isn’t enough pressure in the system for the lifters to pump up correctly and provide adequate lubrication to the valvetrain components. The low oil pressure will cause a loud ticking or knocking sound that is usually more noticeable when the engine is idling. If the oil pressure is too low, it can also lead to further damage to other components such as valves, camshafts, and connecting rods.

A: It is recommended that you replace your lifters every 50,000 miles or so to ensure optimal performance. However, the exact interval may vary based on the type of vehicle and how it is used. If you drive your vehicle in a more demanding environment, such as off-roading or racing, then you should replace your lifters more frequently. Additionally, if you are noticing any signs of wear or performance issues with your engine, then it would be wise to check your lifters as soon as possible.

A: Yes, bad lifters can cause rough idle due to the inadequate amount of oil pressure they supply to the valvetrain components. This lack of lubrication can cause the valves and other parts to stick and move erratically, resulting in a noticeable decrease in power output and an engine that is difficult to keep running smoothly at low speed. Additionally, if left untreated for too long, bad lifters can cause further damage to other components such as valves, camshafts, and connecting rods.

A: Automotive hydraulic lifts are a very convenient and effective solution for many automotive repair and maintenance needs. They come in a variety of sizes, ranging from small two-ton engine hoists to heavy-duty lifts used for semi trucks and buses. Craftsman is one of the more popular manufacturers of two-ton engine hoists. Their models are widely available at local Sears stores or online, and they typically cost under $200.

For professional-grade floor lifts, Rotary Lift is a leader in the industry, offering a wide range of products to meet various needs. Their lifts are capable of lifting an entire car off the floor, though they come with a hefty price tag. Ultimately, the right hydraulic lift for your needs will depend on the size of the job and your budget.

A: Making a hydraulic lifter adjustment requires the right tools and knowledge. Hydraulic lifters are designed to keep the valvetrain free of any clearance, leading to a quieter engine operation. This is done by adjusting the nut on the rocker arm which determines how much clearance is left between the valves and the lifter.

Though it is possible to adjust the lifters on your own, it is often best to leave this task to a professional mechanic. If the adjustment is done incorrectly or too aggressively, there is a risk of damaging the engine. In some cases, hydraulic lifters may have to be replaced instead of adjusted so it’s important to understand which option is best for your vehicle.

A: When shopping for a hydraulic engine lift, you have many options. Auto supply stores are the most obvious choice, and they stock a wide variety of lifts. However, one can also purchase them online from various websites such as Amazon. With a simple Google search, you can find numerous places selling them at reasonable prices.

For example, a two-ton lift can be found for less than $200. This type of lift is perfect for removing engines that require maintenance or rebuilding. In the long run, a hoist like this will pay for itself many times over.

A: Engine hoists are a must-have tool for anyone that works with cars or other heavy machinery. They are used to lift and move heavy engines, transmissions, and other large parts. To ensure that your engine hoist is up to the task, you need to make sure you have the right type of chain.

Hardened steel grade-80 chains are the most common type used for engine hoists due to their strength and durability. These types of chains are designed specifically for overhead lifting, so they are ideal for two-ton engine hoists. Unfortunately, not all big box retailers carry this type of chain, but many will be able to special order it for you.

STREN-FLEX is a great online store for chains and they offer various sizes and strengths. If you’re unsure of which chain to purchase, it is always best to consult the manufacturer’s instructions or ask an expert at your local hardware store. As a general rule of thumb, most two-ton engine hoists will require grade-80 chains. When used correctly, these chains will provide a secure and reliable way to lift your heavy loads.