If you’re experiencing problems with your vehicle, one of the components that you may need to replace is the tie rod end. This component helps connect the steering system to the wheels, so it’s important to make sure that it’s in good condition. In this blog post, we will discuss the symptoms of a bad tie rod end and how much it costs to replace them.

What is a Tie Rod End?

A tie rod end is a crucial part of the steering and suspension assemblies in most cars. It is a small, flexible joint that connects two rigid rods (or control arms) together and allows them to move independently from one another. This movement compensates for variations in road surfaces and helps keep the tires on the ground, providing better handling of the vehicle.

The tie rod ends also help to adjust the toe angle of the wheels, which can affect handling and tire wear over time. Without tie rod ends, a car’s steering would be imprecise and unpredictable.

Tie rods are usually made from high-strength steel or aluminum, depending on the application. These materials are corrosion-resistant and can withstand large amounts of force, which makes them ideal for this purpose. The most common type of tie rod end is the ball joint end, which has a spherical bearing inside that allows movement in any direction.

Tie Rod vs Tie Rod End

A tie rod is a part of the steering system of a car and can be found between the end of the steering arm and the ball joint. It runs along the length of the vehicle’s front axle and its main purpose is to act as an intermediary connecting both ends together. The tie rod is typically secured by two nuts at either end, which is tightened to the desired tension.

A tie rod end, on the other hand, is a part of the suspension system which connects the control arm to the spindle or steering knuckle. It consists of an inner and outer socket connected by a threaded shaft and has two adjustable nuts at either side for adjusting its length as needed. The tie rod end is responsible for allowing the steering arm to pivot as well as providing stability and tightness in the suspension system.

Both tie rods and tie rod ends are essential components of an automobile’s steering and suspension systems respectively, but their purpose and functioning are quite distinct. While tie rods are used to connect various parts of the steering system to the ball joint, tie rod ends serve as a link between the control arm and the spindle. Furthermore, while tie rods are secured by two nuts at each end, tie rod ends feature an inner and outer socket connected by a threaded shaft with adjustable nuts at either side for adjusting its length.

Symptoms of A Bad Tie Rod End

There are a few signs that indicate a bad tie rod end. Here are some of the most common:

Poor Steering Respons

If your tie rod end is bad, you’ll likely notice that turning the steering wheel doesn’t result in as much of a response as it normally would. You may need to turn the wheel several times before you feel it take effect and make a difference in how your vehicle is steered. This is often due to the tie rod end being loose or worn out.

Vibrations In The Steering Wheel

A bad tie rod end can cause noticeable vibrations in the steering wheel when you’re driving on uneven surfaces, such as a city street or gravel road. This vibration could be caused by the loose connection of the tie rod end, or the inability of the tie rod to absorb the shock of bumps on the road.

Clunking And Knocking Sounds

As you turn your steering wheel, you may hear a loud clanking noise coming from the front end of your vehicle. This is often caused by a worn-out tie rod end that has lost its ability to support the steering components. The noise may be louder when turning at low speeds or on uneven surfaces.

Excessive Play In The Steering Wheel

If you have excessive play in your steering wheel, it could mean that your tie rod end is worn out and needs to be replaced. To check if this is the case, try wiggling the steering wheel from side to side. If you can feel a lot of movement in the wheel and it doesn’t move back into place when you let go, then that could be an indication of a bad tie rod end.

Poor Front End Alignment

If you notice that your vehicle’s front end is not aligned correctly, it could be a sign of a bad tie rod end. This can cause your vehicle to drift from side to side and make it difficult to keep the car in a straight line. Poor alignment can also lead to premature tire wear, which will require more frequent replacement of your tires.

Uneven Tire Wear

If your front tires are wearing out faster than the rest, it could be an indicator of a bad tie rod end. A worn-out or loose tie rod end can cause your front wheels to point in different directions, resulting in uneven tire wear. This type of tire wear should not be ignored and you should have the issue checked out by a professional as soon as possible.

If you notice any of these symptoms when driving your car, it may be time to check your tie rod end and replace it if necessary. Regular maintenance, such as checking the condition of your tie rod ends and other suspension components, can help keep your vehicle in good working order for a long time. Failure to replace a bad tie rod end can cause damage to other steering components and lead to costly repairs. Taking the time to inspect your vehicle’s suspension components and replacing any worn parts is a good way to keep your car in good condition.

What Causes Tie Rod Ends to go bad?

Tie rod ends are an integral part of the steering and suspension system in a vehicle. Over time, wear and tear can cause the components of tie rod ends to become damaged or worn out. There are several reasons why tie rod ends can go bad. Here is a quick breakdown of the most common causes:

Age and Wear and Tear

Tie rod ends are made up of a number of different components, all of which can wear down over time. As the vehicle ages and accumulates more mileage, these components become increasingly prone to failure. Heat, dirt, and debris buildup can also contribute to the accelerated deterioration of these parts.

Road Hazards

Hitting large potholes or objects in the road can cause significant damage to tie rod ends. This type of impact can throw off the alignment of a vehicle, resulting in misaligned and loose steering parts. Additionally, hitting even small bumps and curves on the road can cause the components to wear down more quickly than usual.

Tire Problems

Uneven tire wear can also contribute to the deterioration of tie rod ends. If tires are not balanced correctly, it can cause uneven pressure on the suspension and steering system which can put additional strain on the components. This will cause them to break down more quickly than they would otherwise.

Impact Damage

Another common cause of tie rod end failure is damage due to impact. If a pothole or curb is struck with enough force, it can cause the tie rod end to break or be damaged. This will require immediate attention to avoid further damage or potentially dangerous driving conditions.

Lack of Maintenance

Lack of regular maintenance and inspection can also lead to premature wear and tear of tie rod ends. Inspecting the steering system on a regular basis will help to identify any potential issues and allow them to be quickly addressed before they worsen.

Incorrect Installation or Replacement

If tie rod ends are incorrectly installed or replaced, the components may not be able to support the weight of the vehicle properly, causing them to fail prematurely. It is important that these parts are fitted and tightened correctly in order to ensure the safety of the vehicle.

These are just some of the primary causes of tie rod end failure. If you suspect that there is an issue with your tie rod ends, it is important to get them inspected as soon as possible. A qualified professional can help to diagnose the problem and find a solution that is best suited for your vehicle’s needs.

How To Properly Diagnose A Bad Tie Rod End?

Diagnosing a bad tie rod end requires attention to detail and an ability to recognize the tell-tale signs of a problem. There are many ways to do this, including a visual inspection or taking your car to a mechanic for a full diagnosis.

Visual Inspection

A visual inspection is the best way to start diagnosing a bad tie rod end. Look closely at the tires and check for any uneven wear patterns on each tire. This could be an indication of misalignment due to a bad tie rod end. You can also check the steering wheel for any looseness or play while driving, as this could be a sign of a worn-out component.

Mechanic Diagnosis

If you’re still unsure if there’s an issue with your tie rod end after visually inspecting it, then taking your car to a mechanic is the best course of action. A professional will be able to properly diagnose the issue and suggest an appropriate solution. The mechanic may use a tire alignment tool to check for misalignment, as well as inspect the tie rod ends for any wear or damage. They may also recommend replacing the tie rods if necessary.

Once a diagnosis is complete, the mechanic can suggest a course of action to repair or replace the bad tie rod end. They may recommend replacing just one side of the assembly, or both if necessary. In any case, it’s important to follow their advice and get the issue fixed as quickly as possible in order to ensure your vehicle is running properly and safely.

What are the Inner and Outer Tie Rod Ends?

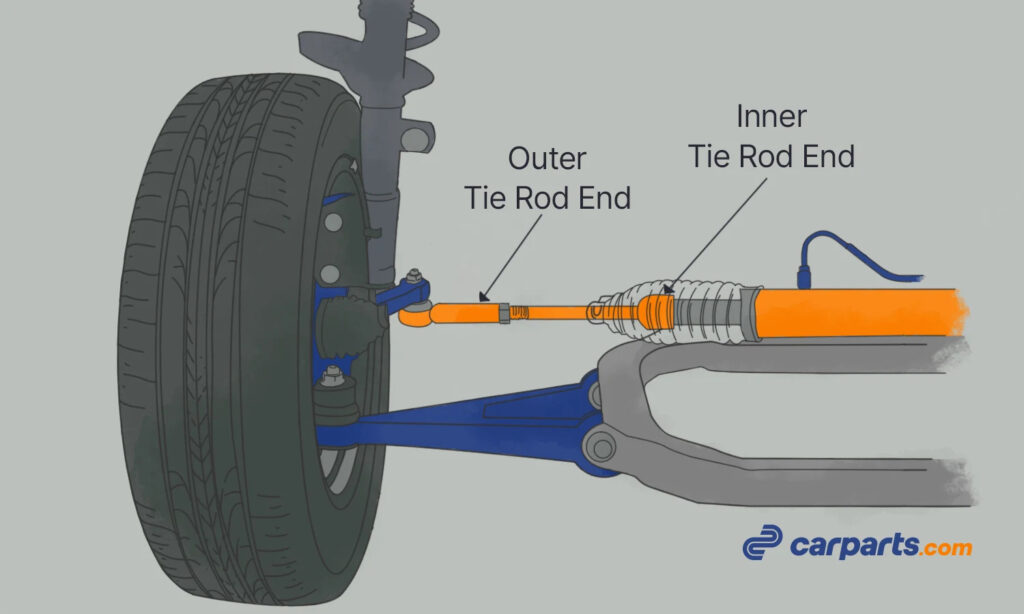

Inner and outer tie rod ends are an integral part of any vehicle’s steering system. The inner tie rod end is connected to the steering gearbox or rack and pinion, while the outer tie rod end is connected to the wheel hub. The two components are connected by a metal rod that is threaded on one end to allow for toe adjustment. This adjustment is typically made by turning the tie rod, which adjusts the distance between the inner and outer ends of the rod to modify toe alignment. This is a common alignment method that is used on all vehicles.

Inner Tie Rod Ends

Inner tie rod ends are a critical component of the steering system in motor vehicles. They are essentially a ball joint attached to the end of the steering rack and are typically hidden from view by an accordion boot that helps to keep dirt out of the rack. The inner tie rod end works in conjunction with the outer tie rod end, by allowing the steering system to move freely while providing stability and strength.

However, due to constant wear and tear, inner tie rod ends may eventually become loose or worn out and thus can pose a safety hazard if there is too much play present. In extreme circumstances, this can lead to the ball coming out of its socket and causing potentially fatal collisions. It is therefore important to regularly check the condition of tie rod ends and replace them when they become too worn out.

Outer Tie Rod Ends

Outer tie rod ends are a critical component of vehicle suspension systems. These parts are located at the end of the rack and pinion steering system and have a rubber boot that helps protect them from dirt, road salt, and water. This prevents the joint from becoming exposed to these elements and wearing down more quickly over time.

In some cases, tie rod ends may come with grease fittings for lubrication purposes. A factory-installed tie rod may not have one of these fittings, but a replacement will usually include it. When the rubber boot covering the joint wears out or is otherwise damaged, it can allow dirt and other particulates to mix with the existing grease, essentially forming an abrasive grinding compound that wears away at the joint more rapidly than usual. Without proper lubrication, any applicable joints could also start to squeak as they move up and down while steering is taking place.

Cost of Replacing a Tie Rod End

The cost of replacing a tie rod end is an important factor to consider when performing maintenance on your vehicle. The cost of replacement can vary depending on the vehicle, the quality of the parts used, and how accessible the tie rod end is. Generally, the cost for parts ranges between $20 and $100 for both inner and outer tie rod ends. Replacing an outer tie rod end typically requires around one hour of labor time, while it may take up to three hours to replace an inner tie rod end due to its more difficult accessibility.

It is recommended that you purchase OEM or high-quality parts in order to get your money’s worth, as labor costs make up almost half of the total cost associated with replacing a tie rod end. Additionally, having a front-end alignment performed at a reputable auto shop after the repair is complete will ensure that your vehicular alignment remains intact and functioning properly.

In order to maximize savings, you should browse around for different repair shops in your area in order to compare labor rates before making a decision. Many independent shops can offer prices significantly lower than those charged by dealerships without sacrificing quality service. Furthermore, it is important to keep in mind that taxes and other fees may be applied to the final price when all is said and done.

On average, replacing a tie rod end can range between $100 and $400 depending on various factors such as vehicle type, quality of parts used, and difficulty accessing the part itself.

Fortunately, there are various ways to reduce this cost such as shopping around for better labor rates or opting for higher-quality parts so that you are able to get maximum value out of your expenditure.

What Happens If You Don’t Replace the Outer Tie Rod?

The outer tie rod is an incredibly important part of a vehicle’s steering system. It connects the steering rack and the steering knuckle, helping transfer input from the steering wheel to the wheels and tires. If not properly maintained or replaced in time, it can lead to a wide range of problems that can be dangerous for both you and your vehicle.

If you neglect to replace the outer tie rod in due time, you could experience premature tire wear as a result of your suspension is out of alignment. If this goes unchecked for too long, it may lead to a tire blowout and even a complete failure of the tie rod itself while driving, resulting in loss of control over the steering. Ultimately, it is highly recommended that you replace the outer tie rod to avoid any potential danger and costly repairs.

How Often to Replace the Out Tie Rod?

Outer tie rods are critical components of your vehicle’s steering system. They are connected to the steering knuckle and help control the direction of the vehicle. It’s important to maintain your outer tie rods in order to ensure that your car is operating optimally and safely. Generally, you don’t need to replace them unless your vehicle has been in an accident or experienced some other damage. In this case, it’s likely that the tie rod ends and outer tie rods will need to be replaced.

DIY Tips for Replacing a Tie Rod End

We may not possess supernatural skills nor are we able to predict the items you need for this job, but here’s a list of everything that is required in order to get it done.

Tool Needed:

- Needle nose pliers or clamp pliers

- Socket set

- Wrench set

- Jack

- Jack stands

- Tie rod puller

- Inner tie rod removal tool

- PB Blaster

- Flathead screwdriver

- Torque wrench

- Thread sealer

Required Parts:

- New tie rod end

- Dust boot and cotter pin (if necessary)

It is essential to arrange your tools and equipment in a way that will allow for easy access. This can save precious moments, eliminating the need to wait on your little one or furry assistant to bring you sandpaper or a blowtorch.

To ensure the job is done right, you’ll need a clear, level surface like your garage floor, driveway, or roadside parking spot. Be sure to check that the area is well-ventilated and double-check with local laws so we don’t have any surprises when it’s time to rev up your ride!

Steps for Removing an old Tie Rod End:

Outer Tie Rod End

- Park the vehicle in a level area with enough room to move around it.

- Make sure that the car is in Park or in gear and engage the parking brake before you start.

- To ensure that the car does not roll, put blocks on the ground wheels.

- Unscrew the lug nuts on one of the wheels using an appropriate wrench and lift up the vehicle using a jack stand.

- Take out the wheel and set it aside for now.

- Spray a penetrating oil such as PB Blaster onto all of the tie rod nuts and bolts to make them easier to remove.

- Loosen the inner/outer tie rod nut by turning it counter-clockwise until you hear a small clicking sound, then unscrew it completely with your hands or a wrench.

- Afterward, locate and remove the castle nut on the outer tie rod end using a wrench, including taking out its cotter pin for safety’s sake.

Once that is done, detach the outer tie rod end from its steering knuckle with either a special tool, such as a tie rod puller tool or use wedges or even a hammer (but try to avoid hitting directly at the bolt). As you do this, pay attention to exactly how many rotations are made so that you can remember them when installing your new part later on.

Inner Tie Rod End

After the outer tie rod end has been removed, the next step is to take out the inner/outer tie rod nut.

- One should use a socket wrench that fits the size of the nut. It is important to make sure that it is securely fastened and tightened in place prior to removal.

- Next, you should remove the dust boot clamps which are located on either side of the inner tie rod end. This can be done by using a flathead screwdriver or pliers.

- Make sure to detach any breather tubes from the dust boot as well.

Once these steps have been completed, you can take off the dust boot itself from its housing on the inner tie rod end.

To finish off this job, you will need to utilize an inner tie rod removal tool which can be rented from any local auto parts store such as Autozone, Advanced Auto Parts, or O’Reilly’s Auto Parts Store. This tool usually includes an adapter and an extension rod that pairs with your ratchet or pry bar for easy attachability and access during operation. To remove the inner tie rod end correctly, insert these components into their corresponding slots and press down firmly until it has come loose and can be taken out of its place without any difficulty.

How to replace Tie Rod Ends?

When replacing the tie rod ends of your car, it is important to make sure that you get the correct parts for your vehicle and that they are the right length and size.

- You’ll need a torque wrench to tighten the connecting nut between the inner and outer tie rods, as well as the castle nuts to manufacturer-specified torque.

- Always apply thread sealer to the inner tie rod end before attaching it to the steering rack.

- Additionally, make sure to double-check and replace any clamps on the dust boot if they are meant for single use only.

- Finally, take the opportunity to inspect your ball joints and CV axles while you’re in the area. This will help prevent any bigger problems down the road.

Alignment

After you replace your tie rods, always drive to a shop for an alignment – it’s essential for optimal performance and safety. An alignment will help ensure your car is in optimal condition and that all of the parts are working the way they should.

It’s important to note that this service needs to be done as soon as possible after replacing any suspension component, such as tie rod ends. This will save you time and money down the road, as it can prevent any bigger problems from occurring down the line.

A car that is properly aligned will experience less wear and tear on its suspension components, as well as more responsive steering and better all-around performance. This can save you money in the long run by prolonging the life of your parts.

Why it’s better to seek out professional services to replace tie rod ends?

When it comes to replacing tie rod ends, many people don’t feel confident tackling the job themselves due to their lack of experience. Professional service providers are essential in this regard because they are experienced and knowledgeable in automotive repair work. Not only that, but they also have access to specialized tools and equipment that make the repairs more efficient and accurate.

The process of replacing tie rod ends is quite complex and requires specific skill sets and precision. Professionals also have the technical know-how to check that all bolts, nuts, and other components are securely in place after installation. This ensures that everything is properly tightened and torqued for a secure fit. Trying to do this yourself could lead to dangerous outcomes and could even cause further damage.

Additionally, professional mechanics have years of experience that can greatly reduce the time it takes to complete the repairs. This is especially true with complex projects like replacing tie rod ends, which require a lot of attention to detail.

What Are The Common Problems After Replacing Tie Rod Ends?

Replacing tie rod ends can be a tricky job that requires precise installation and calibration of the steering system. Once completed, it is important to keep an eye out for any potential issues or problems. Common problems after replacing tie rod ends may include:

Improper alignment

When the tie rod ends are installed incorrectly, it can cause the vehicle to pull to one side during acceleration and deceleration. This may also lead to uneven tire wear and reduced fuel efficiency.

Noisy steering

If the tie rod ends were not greased properly or if they were over-tightened, it could cause a clunking noise that can be heard when turning the steering wheel. This is a sign that something is wrong with the tie rod ends and should be checked by a qualified technician.

Excessive vibrations

Tie rod end replacement that was not done properly can cause excessive vibration in the steering column, which will lead to further wear and tear of the components involved. Proper calibration and alignment of the steering system are essential to avoid this issue.

Loose steering wheel

If the tie rod ends have been overtightened, it can cause excessive friction on the steering wheel, making it very hard to turn and resulting in a lot of play in the wheel. This could lead to dangerous driving conditions and should be checked as soon as possible.

It is important to remember that any problems or issues should be immediately addressed by a professional technician. Replacing tie rod ends can be a tricky process and requires precise installation and calibration, so it is always best to seek out an experienced mechanic if you have any questions or concerns.

Wrapping Up

Despite their small size, tie rod ends play a pivotal role in the safety and stability of your vehicle while driving. It is crucial to be aware of the symptoms of a bad tie rod end, as well as what causes them to go bad, in order to properly diagnose the issue. Replacing a tie rod end can be done at home with some basic knowledge and tools but it is always best practice to seek out professional services to ensure the replacement is done correctly.

There are several common problems that people face after replacing their tie rod ends themselves but these can typically be avoided by visiting a professional mechanic. We hope this article gave you a better understanding of what tie rod ends are, why they go bad, and how to properly replace them. Thank you for reading!