The camshaft position sensor is an invaluable part of a car’s engine, playing a key role in delivering reliable performance and efficiency. As one of the most important components within a vehicle’s engine, it is responsible for providing information related to the position of the engine’s camshaft and crankshaft. This data is used to control fuel injection timing, spark timing, variable valve timing, and other crucial aspects of an engine’s operation. If a camshaft position sensor fails or becomes damaged due to wear and tear or improper use, significant issues can occur which may lead to costly repairs. In this blog post, we will discuss what exactly a camshaft position sensor is, how they work, common symptoms of a bad camshaft position sensor and its causes as well as the cost associated with replacing one.

What is a Camshaft Position Sensor?

A camshaft position sensor is an electronic device used in engines to monitor the rotational speed and position of a camshaft. It does this by measuring the rotation of the camshaft relative to the crankshaft position, and it sends this information to the engine control unit (ECU) so that it can adjust the engine timing accordingly. The camshaft position sensor is an integral part of the engine’s ignition system, as it helps ensure that the spark plugs are fired in the correct order and at the right time for optimal performance. It also allows the ECU to adjust other parameters such as fuel delivery and valve timing.

The camshaft position sensor is typically located in the cylinder head of the engine, often next to or near the camshaft. It consists of a permanent magnet encased in a metal housing, with an internal coil that creates an electromagnetic field when current is sent through it. The sensor measures the rotation of the camshaft by detecting changes in this field as it passes by the camshaft’s lobes. This information is then sent to the ECU, which uses it to adjust the engine’s timing.

Types of Camshaft Position Sensors?

There are three main types of camshaft position sensors (CPS):

Magnetic type sensor

Magnetic-type sensors consist of two wires and generate their own alternating current (AC) sine wave signal that is sent to the engine control module (ECM) for processing. This type is located either in the distributor or on the camshaft, as it has a permanent magnet device attached to it. As the magnet passes through the sensor, its magnetic field creates a pulse that is detected by the ECM.

Hall effect sensor

The hall effect sensor also has three wires: one for reference power, one for ground, and one for sending a signal voltage to the computer. This type also uses a screen with a slot and a magnet mounted on the shaft that turns on or off depending on whether there is a solid area in front of the sensor or not.

A.C. Output Sensor

AC output sensors generate an AC voltage signal as an output. The ECM generates a high-frequency exciter coil which is located near a rotating disc mounted on the end of the camshaft; when this slot passes through the coil, it creates an induction that sends a signal indicating the position of the first cylinder to be sent to the ECM. These types are mostly seen in Vauxhall ecoTEC engines.

Now that you know more about the types of camshaft position sensors, you can make an informed decision on what type might be best suited for your engine. Your mechanic can help you decide which one is right for your car, and he or she can also install it for you.

Common Symptoms of a Faulty Camshaft Position Sensor?

There are several common symptoms of a faulty camshaft position sensor, including:

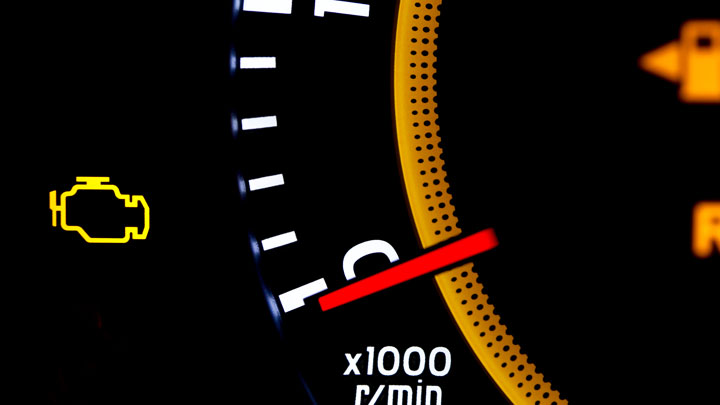

Check Engine Light Illuminates

When the Check Engine light illuminates on your dashboard, it is likely that the camshaft position sensor has started to malfunction. This light can indicate a variety of problems, and you should use an OBD2 scan tool or have a professional mechanic perform an inspection of the engine control module in order to receive any diagnostic trouble codes that are stored.

Ignoring the Check Engine light could lead to serious damage to the engine, including possible failure and the need for a rebuild or replacement. Therefore, it is essential that you scan your car or have it inspected as soon as possible when this warning light turns on in order to avoid further costly issues.

Ignition Problems

Another common symptom of a faulty camshaft position sensor is ignition problems. This can include misfires, rough idling, and an inability to maintain the correct engine speed. Additionally, this problem can lead to decreased gas mileage and sluggish acceleration due to the incorrect amount of fuel being injected into the cylinders.

Bad Fuel Economy

When it comes to fuel economy, a poorly functioning camshaft position sensor can be the source of the problem. This vital component is responsible for providing data to the engine computer which regulates and controls the fuel delivery system. If it fails, it may provide incorrect information to the ECU, resulting in either too much or not enough fuel being delivered.

This can lead to poor engine performance, knocking, and reduced fuel efficiency, as well as more serious damage if the issue is not addressed. Therefore, it is important to ensure that this sensor is functioning correctly in order to maximize fuel economy.

Rough Idling

Rough idling can be an annoying problem for many engine owners. It is caused by a number of issues, such as a malfunctioning camshaft position sensor, a faulty idle fuel pump, or a problematic exhaust gas recirculation valve. When the camshaft sensor malfunctions, it causes asynchronous combustion in the cylinder and subsequently causes a rough idle. To diagnose and fix the issue, it is important to have the right tools and knowledge of what could be causing the problem. Professional help may be required in some cases.

Poor Acceleration

The symptom of a faulty camshaft position sensor is poor acceleration. This can be caused by the incorrect timing of the combustion cycle, which results in inefficient burning of fuel and decreased power output. Additionally, this can result in an engine that has difficulty responding to throttle inputs or stalling when you are attempting to accelerate quickly.

Car Jerking or Surging

Car jerking or surging is another symptom of a faulty camshaft position sensor. This can be caused by incorrect information being sent from the camshaft position sensor to the engine control module and cause your vehicle’s RPMs to increase or decrease rapidly. This symptom can be especially dangerous if it occurs while you are driving, as it can cause your vehicle to lose control and put you or others in danger.

Problems Shifting

Problem shifting can be a sign of a faulty camshaft position sensor. This can cause the transmission to become stuck in one gear or have difficulty shifting between gears. In some cases, it may even cause your vehicle to slip out of gear while driving, which can be dangerous and lead to an accident if you are not careful.

Gas Smell

A malfunctioning camshaft sensor can have dire consequences for the performance and safety of a vehicle. This is because it has the potential to create a buildup of unburned fuel in the exhaust system, resulting in decreased fuel economy and black smoke being emitted from the tailpipe. Not only is this an unwelcome sight, but this unburned fuel gas can also produce a strong, pungent smell that is hazardous to humans.

Engine Misfire

A faulty camshaft position sensor can lead to a slew of issues with a vehicle’s performance. The signal it sends is essential for the proper operation of the fuel injectors, as well as most timing-based engine functions such as spark control.

When this piece fails, drivers may notice a variety of symptoms including reduced acceleration and power, a Check Engine Light on the dashboard, and engine misfires which can cause vibrations while accelerating. If these symptoms persist, it is recommended to look up your car’s trouble codes as soon as possible in order to diagnose and fix the issue.

These are the common symptoms of a faulty camshaft position sensor. If you experience any of the above issues it is important to get your car looked at by a professional as soon as possible, since these problems could have serious consequences for the safety and performance of your vehicle.

What causes Camshaft Position Sensor to go bad?

There are several potential causes of a faulty Camshaft Position Sensor that may lead to engine failure and other related problems. Here are some of the most common causes:

Worn or Damaged Wiring

One of the most common issues associated with camshaft sensors is a problem with their wiring harnesses. In particular, this can occur when the voltage is not at the right level or when there are problems with the return or ground circuits. These issues can be compounded if there is dirt, debris, or oil on the wiring harness that disrupts the voltage, leading to the wiring becoming worn out or otherwise damaged. This in turn can lead to camshaft sensors failing repeatedly and causing your car to start up again and again, making it difficult for the engine to run continuously for long periods of time.

Oil Leaks and Sludge Buildup

Oil leaks or sludge buildup can also cause problems with a camshaft position sensor. If oil is allowed to leak into the wiring or around the sensor, it can disrupt the voltage and lead to sensor failure. This is why regular oil changes are important – they help reduce the chances of a buildup forming in your engine that could damage its components.

Faulty or Outdated Camshaft Sensors

Another potential reason why your camshaft position sensor may be failing is if it is an old or outdated model. As with many electrical components, the designs of camshaft sensors can change over time, making older models less effective. If your car has been on the road for some time and still has an outdated camshaft sensor, then it may no longer be able to accurately read the position of your vehicle’s valves, leading to engine performance issues.

A crank Walk is a condition that occurs when the crankshaft of an engine slips out of position in relation to the engine’s belt. Over time, this can cause serious damage to the crankshaft and result in engine failure without warning.

Crank Walk

The main reason for crank walk is due to wear and tear on the main thrust bearing. As the crankshaft slowly moves out of place, it will begin to make a clicking sound with each revolution of the engine’s belt. This indicates that the crankshaft is undergoing serious wear and tear and should be inspected immediately before any further damage occurs.

If left unchecked, the crank walk can cause complete failure of the crankshaft, leading to a complete shutdown of the engine. To prevent this from happening, regular maintenance and inspection should be done to ensure that all components are functioning properly. If any signs or symptoms of crank walk appear, it is essential that the crankshaft be checked by a qualified mechanic right away.

Over Heating

When driving your car for long periods of time, especially on hot days with direct sunlight present, can put a lot of strain on the engine and its components. The intense heat can cause damage to the camshaft sensor, which is located in the engine block. This part is responsible for controlling the timing and opening of valves, as well as ignition and fuel injection. When exposed to extreme temperatures, the plastic casing around the crankshaft sensor starts to crack or melt, causing your car not to start up afterward.

Moreover, when your vehicle is operating for long periods of time, it produces a great deal of heat within the engine itself. Factors such as inadequate ventilation, lack of lubrication, and a faulty radiator can cause the engine to overheat. This can lead to further problems if not taken care of quickly, so it is important to monitor your car’s temperature regularly while driving.

Prior Accidents

Accidents, even if seemingly minor, can have an effect on the functionality of your vehicle. Even if it looks alright from the outside, some components may have sustained damage from a collision. This could be anything from broken wires to loose oil caps and damaged oil tanks. All these malfunctions can disrupt the signals sent by your camshaft sensor since the camshaft is connected to other engine parts. Thus, a previous accident may be at fault for your current issue.

Timing Belt

When it comes to engines, the timing belt is a critical component that keeps everything running smoothly. It helps keep the camshaft and crankshaft rotating in sync with one another and ensures that the engine has optimal power during operation. Unfortunately, if this belt is damaged due to an accident or collision, it can cause major problems for the engine.

When the timing belt tears or snaps, it can wrap around the crankshaft and damage other parts and sensors, such as the camshaft sensor. This can result in damage to the wiring harness and sensors too. Although the timing belt itself can be replaced, this won’t fix the other damages that were caused by it. To properly repair the engine, the camshaft sensor must be replaced as well.

Checking The Camshaft Position Sensor: Troubleshooting

To check the camshaft position sensor, you need to first inspect it for any damage or wear and tear. You should also read out the fault memory from the control unit as this can sometimes help identify any potential issues. Troubleshooting a camshaft position sensor is an important part of engine maintenance. Here is how to do it:

Check the connection line

When verifying the camshaft position sensor, it is important to accurately test the connection line from the control unit to the sensor. This can be done by disconnecting both ends of the connector and using an ohmmeter to measure the individual cables for continuity. A circuit diagram should be consulted for pin assignment reference values, which should indicate a value of approximately 0 Ohms.

Check the connection lines for a short circuit to frame

Next, you’ll need to check the electrical connections of the sensor’s wiring, connector, and a sensor for correct connection, breaks, or corrosion. This involves checking each individual cable for continuity using an ohmmeter and verifying that there are no short circuits between the connection lines and frame. The reference value here should be higher than 30 MOhms.

Check the supply voltage

Additionally, you should measure the supply voltage from the control unit to the sensor with an ignition switch on; reference values should be around 5V depending on manufacturer specifications.

Check the signal voltage

Lastly, use an oscilloscope to check the signal voltage by connecting one end of its measuring cable to the sensor while starting up your engine. Upon doing so, a square wave signal should appear on your oscilloscope indicating the proper operation of your camshaft position sensor.

All these steps will help ensure that your engine is running smoothly and efficiently.

Camshaft Position Sensor Replacement Cost

Replacing a camshaft position sensor can be an expensive endeavor, with costs ranging from around $95 up to $200. Depending on the make and model of your vehicle, the parts alone will set you back between $25 and $100. Labor costs associated with professional installation typically run between $70 and $100. However, if you are driving a luxury car or having the work done at a dealership, you should expect to pay more. Additionally, any applicable taxes and fees will also be added to the final bill.

Can You Replace a Camshaft Position Sensor Yourself?

Replacing a camshaft position sensor is an easy job that can be undertaken by just about anyone. All that is required is a few simple tools, and it should take no more than 10 minutes. Doing the job yourself can help you save money since repair shops and dealerships often have labor fees of around $100 to do the same job.

How to Replace a Camshaft Position Sensor

Replacing a camshaft position sensor is an important maintenance activity for any vehicle owner. It is typically located on the top, front, or rear part of the engine, and is usually held in place with an 8mm or 10mm bolt.

Step 1

Before beginning this process, it is essential to disconnect the negative battery cable and release the tab on the wires attached to the sensor.

Step 2

The next step to replacing a camshaft position sensor is to remove it from its mounting bolt. This requires using a wrench to carefully loosen and then remove the bolt that holds it in place. With caution, pull off the sensor with a slight twist motion.

Step 3

To install a new camshaft position sensor, apply some engine oil to its o-ring first so that it will slide into place more easily and securely.

Step 4

After attaching and tightening up its mounting bolt, reconnect its wire connector and re-attach the negative battery terminal.

While it might seem like a daunting task at first glance, following these simple steps will allow anyone to quickly and accurately replace their vehicle’s camshaft position sensor without having to bring it into a shop or mechanic. Doing this regularly will help keep your car running smoothly for years down the road!

Closing It Up

In conclusion, a faulty camshaft position sensor can cause a variety of issues with your vehicle’s performance. Common symptoms include rough idling, poor acceleration, poor idle quality, car jerking or surging, problems shifting gears, gas smell, and engine misfires. It is important to make sure that the camshaft position sensor is functioning correctly in order to ensure that your vehicle is running optimally and safely. Replacing a camshaft position sensor is an easy job that can be done with a few basic tools, and doing it yourself will save you time and money. If you let your mechanic replace the sensor for you, It will cost around $95 up to $200.Make sure to get a quote and shop around for the best prices. With regular maintenance and a bit of TLC, your car can last for many years to come!